FITZER INCORPORATION

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to FITZER INCORPORATION

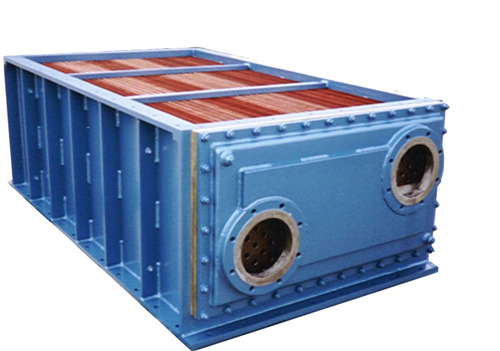

Shell And Tube Heat Exchanger

Shell and Tube Heat Exchangers Manufacturer INDIA

Shell and Tube Heat Exchanger is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. Shell Tubes Heat Exchanger are classified into fixed and Floating type Heat Exchangers . Fixed type Heat Exchangers are used where there are absolutely no chances for inter mixing of two fluids.

Shell and tube heat exchangers consist of a series of tubes. One set of these tubes contains the fluid that must be either heated or cooled. The second fluid runs over the tubes that are being heated or cooled so that it can either provide the heat or absorb the heat required.

In this type, the tube sheets are completely welded to the shell and acted as shell flanges. The Floating type Heat Exchangers has the advantages of removability of tube bundle and access for cleaning both inner and outer side of tubes and shell.

Shell And Tube Evaporator

The main function of Shell & Tube Type Evaporator is to act as a heat exchanger in a vessel form. This is mainly done to cool closed circuit for re-circulating fluid flow. This can be done with the help of refrigerants as a cooling medium. They are efficient in working and having compact design. The concept of the equipment is based on large number of tubes that can be formed into bundles. The refrigerants passed through the expansion device that passed into tubes and evaporates to produce a cooling effect.

Features

- Low maintenance

- High working efficiency

- High grade material

- Meets standard norms

- Longer service life

- Ergonomic design

- Easy to use

- Simple operation

Shell And Tube Oil Cooler

We are leading Manufacturer of Shell and Tube Oil Coolers and our product is made up of good quality.

Our company is well known in the market and they have been made using the best technology available in the market.

The range of products which we offer to the customers are inclusive of the Shell and Tube Oil Coolers which transfer the heat in a very effective manner and these coolers are high on demand in the marine sectors and in the diesel engines.

These products have been priced at very reasonable and affordable rates in the market.

Features

- Reliable

- Long lasting

- Non-corrosive.

Tube Bundle Heat Exchangers

Tube Bundle Heat Exchangers

U Tube bundle Heat Exchangers can duplicate any existing bundle to include dimensions, materials and performance.

A heat-exchanger system consisting of a bundle of U tubes hairpin tubes surrounded by a shell outer vessel. One fluid flows through the tubes, and the other fluid flows through the shell, around the tubes.

One of the most common applications is the cooling of Hydraulic Fluid. And oil in engines, transmissions and hydraulic power packs.

With the right choice of materials they can used to cool or heat other mediums. Such swimming pool water or charge air.

Air Cooled Heat Exchange

Air cooled Heat Exchanger

Air cooled Heat Exchangers (or) Fin fan Cooler or Air Fin Cooler are the same Air Cooling equipment. In some part of the world Air Cooled Heat Exchangers also known as Air Fin Cooler. Simply says Air Fin cooler, Fin Fan cooler, Coil Cooler, Dry Cooling Tower the other names of Air Cooled Heat Exchangers. It also used for Heat rejecting from a hot process fluid to the surrounding atmosphere by using the atmospheric air as a cooling media.

The Air Fin Coolers basically designed with multiple rows of finned tubes in a series of surface and required numbers of fans used to move the low temperature atmospheric ambient air over the finned tube coil surface in order to cool the hotter fluid media. It is nothing but an extended type of industrial or automotive radiators. The finned tube bundles are modular construction for easy transportation. The various types of headers Welded Bonnet Header, Plug Header, Manifold header, Plug and pipe header etc.,

The various types of Fins are ‘L’ type Wrap-On Fins, ‘G’ type Embedded Fins and Bi-metallic Extruded Fins etc.,. In some small type heat Exchanger wire/ strip type copper wounded / knurled Fins also used. Other than finned tube bundle and headers, Axial flow fans and drives etc are used as per the Cooler requirement.

These Air Cooled Type Heat Exchangers used in oil, gas, petrochemical, refinery, power and condensation plants. All type of fluids in process industries cooled in Air Fin Coolers with the use of atmospheric air, as the cooling media which resulting in economy in running costs.

Our Air Cooled Heat Exchangers are used for high pressure, high temperature applications in process industries with metallurgy suitable for highly corrosive fluid medias.

Finned Tube Heat Exchanger

Finned Tube Heat Exchangers are a special European technology. In which continues wire or strip of fin material wounded spirally on the tubes and strengthened to withstandard higher internal pressure comparing with radiation type.

Our range of finned tube heat exchangers built on specialized European technology. That helps our products to with stand higher internal pressure. Finned Heat Exchangers having more heat transfer area, which allowed to improve the efficiency.

MATERIALS:Tubes, Tube sheets, shells, Baffles and Fins of Heat Exchanger are made out of various custom required material & TEMA Standards like seamless or ERW tubes and shells in Copper Aluminium, Brass, mild steel, cupro Nickel, Aluminium brass and stainless steel, carbon steel, admiralty Brass materials are used. The end of the tubes probably welded or expanded with grooved tube plates. By tube expanding machines up to a pressure level of 1000 PS1 Pressure.

QUALITY: Heat Exchangers carefully designed and tested from selection of raw materials. As per specifications and the quality tested with its own quality control departments. X-Ray Hydraulic, Pneumatic, penetration testing the series of regular tests routinely adapted by Fitzer to confirm and witness the quality as per standards. Also Third party inspection agency like Lloyds Register, IBR,RITES and Engineers India also arranged for Quality assurance.

PRODUCT RANGE:Water Heat Exchangers for process cooling, Generators etc. Oil coolers for Hydraulic quenching oil, transformers, gear boxes etc. Inter/After Coolers for Compressors, Condensers, Chillers, Evaporators, Air Blast oil coolers, Pressure vessels, Heat Exchangers & oil coolers for marine Air heaters, Tray driers for tea, leather etc. Wire/strip wounded fin type coolers for process cooling Hydraulic. Rig Compressors, Railways, Earth movers, Genset air coolers, Gas coolers, Dry Cooling Towers etc manufactured.

Fin Fan Cooler

The Air Cooled Heat Exchangers also known as Fin fan Coolers. Fin Fan Cooler is nothing but traditional name of Air Cooled Heat Exchanger. Since Fins are used in the Cooler it is called as Fin fan Cooler. Please refer Air cooled Heat Exchanger for all the details. In the Fin fan coolers, the ambient air used as the cooling media to cool.

the main hot fluid which used in tube side. All the tubes used in the coolers finned tubes only. The finned tubes are having more contact surface , hence the fin fan cooler one of the best closed circuit and water savable cooling system.

Finned Tube Type Industrial Dehumidifier

MAIN FEATURES

Finned tube heat exchanger type for dehumidification of air by means of condensation by using ice water or other cooling media flowing through the heat exchanger tubes, followed by a demister and re-heater (steam or hot water) to heat up the air above the dew point

Customized according to client specification and request

Insulated housing (fully welded, sanitary design) and extractable elements

MATERIALS AND CHARCTERISTIC VALUES

- Housing: Stainless steel (AISI 304 and AISI 316) with mineral wool insulation

- Finned tubes: Stainless steel (AISI 304 or AISI 316)

- Fins: Aluminum or stainless steel

- Demister: Stainless steel (AISI 304 and AISI 316)

- Energy transferring media like water, glycol water, refrigerants or other medias possible

- Air volume: up to 200’000 kg/h per device

- Air outlet humidity: down to 5-6 g/kg

Fin Tube Air Heaters

The wide assortment of Finned Tube Air Heaters offered by us highly acclaimed by clients. We use quality assured raw material for making our range durable and rigid in construction. These Finned Tube Air Heater are widely used in many areas such as pharmaceutical dryers, chemical, food dryers, textile processing, and oil extraction plants. Apart form this; Finned Tube Air Heaters are also applicable in dairy, ice-cream plants, power plants, refineries, earth moving, petrochemicals and air compressors.

Fin Tube Flue Gas Air Pre Heater

An air preheater (APH) is a general term to portray any gadget intended to warm air before another procedure (for instance, burning in a kettle) with the essential goal of expanding the warm productivity of the procedure. They might be utilized alone or to supplant a recuperative warmth framework or to supplant a steam loop.

Specifically, this article portrays the burning air preheaters utilized in huge boilers found in warm power stations delivering electric power from e.g. petroleum derivatives, biomasses or waste.

The motivation behind the air preheater is to recuperate the warmth from the kettle pipe gas which expands the warm productivity of the heater by decreasing the helpful warmth lost in the pipe gas. As an outcome, the pipe gases are likewise sent to the pipe gas stack (or smokestack) at a lower temperature, permitting rearranged plan of the ducting and the vent gas stack. It likewise permits control over the temperature of gases leaving the stack.

Types: Tubular Type Regenerative Air Preheater Rotating Plate Regenerative Air Preheater Stationary Plate Regenerative Air Preheater

Kettle Reboiler Type Heat Exchanger

Kettle reboilers are very simple and reliable. They may require pumping of the column bottoms liquid into the kettle, or there may be sufficient liquid head to deliver the liquid into the reboiler. In this reboiler type, steam flows through the tube bundle and exits as condensate. The liquid from the bottom of the tower, commonly called the bottoms, flows through the shell side. There is a retaining wall or overflow weir separating the tube bundle from the reboiler section where the residual reboiled liquid (called the bottoms product) is withdrawn, so that the tube bundle is kept covered with liquid.Kettle reboilers are reliable in that they can handle high vaporization of up to 80 percent and are easy to maintain. The liquid from the bottom of the tower flows through the tube bundle and exits as condensate. A restraining device (baffle) controls the liquid level over the bundle.

Specifications

Proper reboiler operation is vital to effective distillation. In a typical classical distillation column, all the vapor driving the separation comes from the reboiler. The reboiler receives a liquid stream from the column bottom and may partially or completely vaporize that stream. Steam usually provides the heat required for the vaporization.

Applications

The high level of vaporization makes it prone to fouling, and these reboilers are expensive due to their large shell size and maintenance.

Radiators

where we are pleased to introduce ourselves as a proficient manufacturer and exporter of several types of radiators. We started with our journey way back in the year 1995 and the consistent success that we have gained in all these years is due to the sincere efforts laid by our professionals. The high end radiators that we offer for different industrial goods likeTransformer Radiators, Hot Dip Galvanize Radiators, Offset Radiators, Pressed Steel Radiators, Graded Panel Type Radiators and many more are of world-class quality.

The radiators we provide are available in different specifications so that they can meet with the application needs of power generation and electrical industry efficiently. For example the transformer radiator we offer increase the cooling speed of transformer and therefore, plays a significant role in increasing the transformers loading capacity. The team of engineering experts that we have recruited in our company to engineer these goods has sound experience of this industry/ field and thus, the entire fabrication work is done in accordance to the standards set by the authorized engineering industry.

Marine Heat Exchangers

Marine Heat Exchangers exhaust manifold is necessary on marine engines. To reduce the temperature of the engine-room air space and the exhaust pipe. Our development is to combine a water jacketed exhaust manifold with the heat exchanger and header tank. This arrangement particularly suitable for small series-produced engines; the manifold cooled by fresh water and a result a keel-cooled engine. It can made by omitting the heat exchanger tube stack and the sea-water pump. On installation the fresh-water outlet from the manifold would connected to the keel pipes and the return taken back to the engine fresh-water pump.

Heat exchanger/manifold assemblies are heavier than ordinary marine manifolds. And must supported on the underside using the fixing lugs provided. If the exhaust manifold is in the sea-water circuit it should be installed with the sea-water inlet at the back and the outlet at the front on the top. To ensure that it operates completely full of sea-water. If the manifold is in the fresh-water circuit a small by-pass hole must be provided in the thermostat to ensure that some water is circulating through the manifold at ail times.

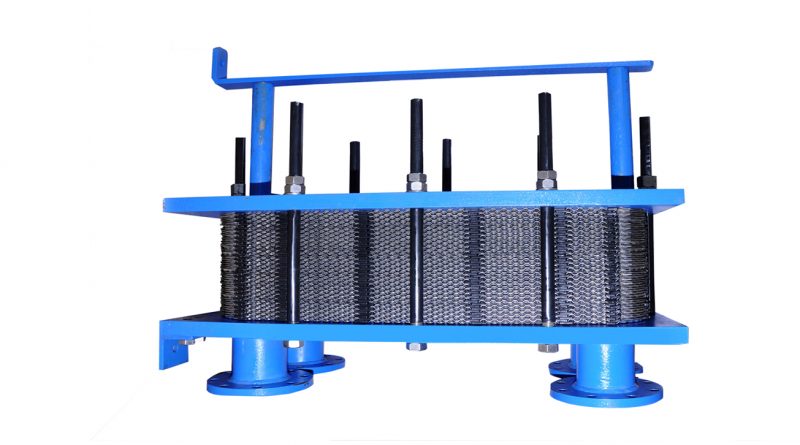

Plate Type Heat Exchanger

In Heat exchanger system, the new and latest type of compact and effective model Heat exchanger is plate type heat exchanger. Another type of heat exchanger is the plate heat exchanger. One composed of multiple, thin, slightly-separated plates that have very large surface areas and fluid flow passages for heat transfer. This stacked-plate arrangement can be more effective, in a given space, than the shell and tube heat exchanger.

Advances in gasket and brazing technology have made the plate-type heat exchanger increasingly practical. In HVAC applications, large heat exchangers of this type called plate-and-frame; when used in open loops, these heat exchangers are normally of the gasketed type to allow periodic disassembly, cleaning, and inspection. There are many types of permanently-bonded plate heat exchangers. Such as dip-brazed and vacuum-brazed plate varieties, and they are often specified for closed-loop applications such as refrigeration. Plate heat exchangers also differ in the types of plates that used, and in the configurations of those plates. The closely spaced metal heat transfer plates have troughs or corrugations. Which induce turbulence to the liquids flowing as a thin stream between the plates.

The plates have corner ports. Which in the complete plate pack form a manifold for even fluid distribution to the individual plate passages. As an exclusive feature, parallel flow heat exchanger plates have interlocking gaskets. In which upstanding lugs and scallops are sited intermittently around the outside edges. The seal between the plates is established by a peripheral gasket which also separates the thru port and flow areas with a double barrier. The interspaces vented to atmosphere to prevent cross-contamination in the rare event of leakage. Plate heat exchanger, consists of a stationary head and end support connected by a top carrying bar and bottom guide rail. These form a rigid frame, which supports the plates and moveable follower. The closely spaced metal heat transfer plates have troughs or corrugations. Which induce turbulence to the liquids flowing as a thin stream between the plates.

The plates have corner ports, which in the complete plate pack form a manifold for even fluid distribution to the individual plate passages. For further details for plate heat exchanger, please contact our marketing division.

Brazed Plate Heat Exchanger

We are the leading manufacturers of Air heat exchangers in India.

Brazed Plate Heat Exchangers represent the most compact, rugged and cost-effective means of transferring heat in many industrial and refrigerant applications. Built from 316 stainless steel with copper brazing materials, they provide exceptional corrosion resistance. The SB-Series features corrugated plates that produce highly turbulent flow in a true counter-current direction.

This results in high efficiency and a very compact heat exchanger design. Due to the smaller size and reduced material content, they can be the most economical heat transfer choice.API Heat Transfer Brazed Plate Heat Exchangers are available for process and refrigeration applications. Made from stainless-steel plates and copper or nickel brazing materials, they are suitable for a wide variety of heat exchanger applications.

Specifications

- The brazed plates form two separate channel systems.

- The two media assume a true countercurrent flow, completely isolated from each other.

- This channel configuration is designed to produce high turbulence, promoting maximum heat transfer.

Sprial Heat Exchanger

We are occupied in providing Spiral Heat Exchanger to all customers of chemical and pharmaceutical industries. These exchangers are widely demanded due to highly efficient working and availability in numerous configurations. Our optimum quality involved exchangers are completely safe from the adverse effects and high temperature. Easily available in market at reasonable price our spiral heat exchangers are made from quality approved material which is procured from certified sources.

Features

- Mesmerizing range

- Perfect shape

- Unmatched finishing

Description / Specification of Sprial Heat Exchanger

We are involved in offering a wide range of Sprial Heat Exchanger to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Sprial Heat Exchanger. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.